We’ve heard a lot about hydrogen for many years now : “as the energy platform of the future”, “as a means to move away from fossil fuels”. But all that has yet to happen. We still don’t use Hydrogen in our daily lives. What are the problems? When will it really happen? What does it take to make it happen? Let’s try to find answers to all these questions.

The answer to the second question is sooner than you think. With constant increase in world energy demand, usage of fossil fuels is increasing. Carbon dioxide and other greenhouse gases cause global warming and air pollution. Transition to a cleaner fuel is therefore the need of the hour. Hydrogen has successfully demonstrated its important role in this transition. What remains is realizing it. In this blog, we discuss how Hydrogen as an energy source can truly be a part of our daily life.

Knowing Hydrogen

Hydrogen is the simplest element that exists. It is the most abundant element in our universe and one of the most abundant on the earth’s crust. At standard temperature and pressure, hydrogen is a non-toxic, colorless, odorless, tasteless and the least dense gas. However, most of the hydrogen on earth does not exist as a gas but it is present in a molecule form with other elements such as water and organic compounds.

Hydrogen can be considered as the simplest energy carrier and has several advantages. Hydrogen has the highest energy content by weight, combustion of 1 kg hydrogen has 2.8 times greater energy output than the combustion of 1 kg gasoline. It can be produced by splitting water using renewable energy sources. When combusting hydrogen, electricity and water is produced which does not cause air pollution. Therefore a sustainable economy based on hydrogen can be achieved. In the following part, we look into the different production methods of hydrogen.

How is hydrogen produced ?

Conventional processes

Today, roughly 95% of hydrogen is produced from fossil fuels. Conventional way is thermochemical processes by natural gas reforming such as steam-methane reforming and partial oxidation.

In steam-methane reforming high pressure steam reacts with natural gas in presence of a catalyst. Hydrogen, carbon monoxide and relatively small amounts of carbon dioxide are the products. Subsequent to this reaction, a water gas shift reaction occurs. Here hydrogen and carbon dioxide is formed from steam and carbon monoxide in presence of a catalyst. Finally, hydrogen is separated from the gas mixture and the impurities.

In partial oxidation, methane reacts with oxygen to form carbon monoxide and hydrogen. It is important to keep the amount of oxygen limited to avoid complete oxidation of hydrocarbons to carbon dioxide and water. After this partial oxidation, water gas shift reaction occurs and then the products are separated. Compared to steam-methane reforming, this partial oxidation is faster.

Hydrogen production from fossil fuel is also possible via pyrolysis. In this method, additional reactants such as water of oxygen are not required and the hydrocarbon is the only hydrogen source. Thermal decomposition of hydrocarbon produces hydrogen and elemental carbon.

Upcoming processes

Next to the production from fossil fuel, hydrogen can be produced by water splitting through processes such as electrolysis and thermolysis. For electrolysis, a unit called electrolyzer is used. Electrolyzer is composed of an anode and a cathode immersed in an electrolyte. When applying electricity, a water splitting reaction occurs and hydrogen is produced at the cathode while oxygen is produced at the anode. This production method leads to a very pure hydrogen. This is a well developed technology but the high electricity consumption results in high production cost compared to the conventional method, leading to only 5% of hydrogen produced in the world. However, this technology can be integrated with renewable energy sources (e.g. photovoltaics) for a sustainable and more cost effective hydrogen production in the future.

Thermolysis is a thermochemical process in which water decomposes to hydrogen and oxygen at a very high temperature. In general, water decomposition occurs at a temperature above 2500 degree Celsius. This condition cannot be achieved using sustainable heat sources. To lower the operating temperature, thermochemical cycles consisting of a set of chemical reactions have been proposed. This enables it to produce hydrogen at temperature below 1000 degree Celsius, but it also faces disadvantages such as material corrosion and elements toxicity.

Another technique to produce hydrogen is by direct solar water splitting which involves sunlight and semiconductors to dissociate water into oxygen and hydrogen. Hydrogen can also be produced by biological processes using microbes. Both processes are still under development, but there are many groups doing research in these fields (e.g. Researchers in TU Eindhoven on solar water splitting and University of Birmingham on biological hydrogen production). Both technologies have the potential to produce hydrogen in a sustainable way.

Hydrogen vs other fuels

Let’s now have a look at what makes Hydrogen different from other fuels out there. There are pros and cons for each aspect. All of these aspects need to be correctly weighed together to determine if Hydrogen is indeed a superior fuel as compared to others. Let’s look at the upsides first.

Upsides

Emissions

Hydrogen emits no greenhouse gases or other pollutants when burnt. On the other hand combustion of fossil fuels are among the largest contributors towards atmospheric pollution. Even the production of hydrogen via electrolysis does not contribute to greenhouse gases assuming the energy required for this process comes entirely from renewable resources.

Safety

Hydrogen is lighter than natural gas, propane, approximately 57 times lighter than gasoline vapor and 14 times lighter than air. This means that if it is released in an open environment, it will typically rise and disperse rapidly. This is a good safety advantage in an outside environment compared to other fuels. The auto-ignition temperature of Hydrogen is much higher compared to gasoline vapor.

Challenges

We have a lot of promising new technologies to produce Hydrogen which are greener and sustainable. These novel technologies do not use fossil fuels as a primary raw material. So why then we don’t adopt them already? Some of the challenges for total adoption are economic viability, storage safety, adoption and competition with heavily optimized supply chain and infrastructure of fossil fuels. Let’s have a look at them.

Costs

Inexpensive production of Hydrogen is still not practical. In addition to it, safe handling and storage cost more. In comparison to that, fossil fuels are cheaper, safer to use and store.

Safety

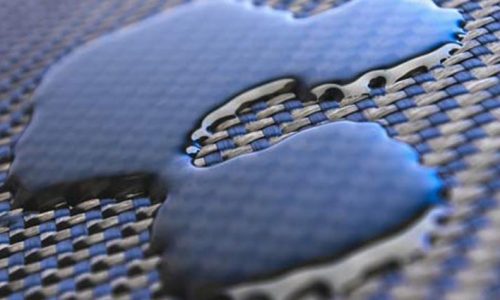

The use of hydrogen as an energy source will also face some challenges. Since hydrogen has a low ignition energy and high energy output, safe use needs to be ensured. Another challenge is the required high volume and high pressure for the storage of hydrogen. The energy content of hydrogen by volume is more than 4 times smaller than the energy content of 1 L gasoline. The need of a completely new infrastructure with hydrogen based applications is also a challenge.

Production

Although hydrogen is the most common element in the universe, it does not exist in its pure form on earth. The hydrogen needs to be produced in a sustainable and clean way. Most hydrogen fuel produced today is obtained by the process of natural gas reforming. This process has by-products such as carbon dioxide and carbon monoxide, contributing to global warming.

Takeaways

The current primary sources of energy are still the fossil fuels. Given the limited nature of these reserves which are fast depleting, big brands, manufacturers and governments are looking for alternative renewable sources. Recently, Scotland was in news to be the first in the world to test 100% green Hydrogen to replace natural gas for cooking and heating in 300 homes.

H2Pro, the winner of the 2020 Shell New Energy Challenge has demonstrated an efficient, affordable, safe and sustainable production of Hydrogen via a novel water splitting technology called E-TAC (Electrochemical, Thermally Activated Chemical). According to H2Pro, E-TAC is relatively simple to manufacture, promising low capital costs and is highly scalable.

While it is still at the experimental level and in some cases pilot level, Hydrogen has great potential to be the primary source of energy for mankind. Whether and when that happens needs to be seen. Based on current interest and developments, it appears that the day is not far when you stop the car at the hydrogen fuel station.

We had a look at a number of different production methods of hydrogen. None of these is yet entirely ready to completely replace the fossil fuel based society. A number of companies in the energy sector are eagerly looking for best solutions to solve this long hanging problem.

Simreka has extensive expertise and knowledge in innovative state-of-art solutions for chemical processes from an environmental, financial and safety perspective. This expertise has helped existing customers’ decisions on production methods to use, improving and optimizing processes and developing the most profitable and environmentally friendly pathway.